Is your company looking to create a new product? Does that product need a cool looking rendering to help get people onboard with the idea? Do you need someone to help manufacture, assemble and test the prototype? If so, we can help with all of that. Here is how we can help:

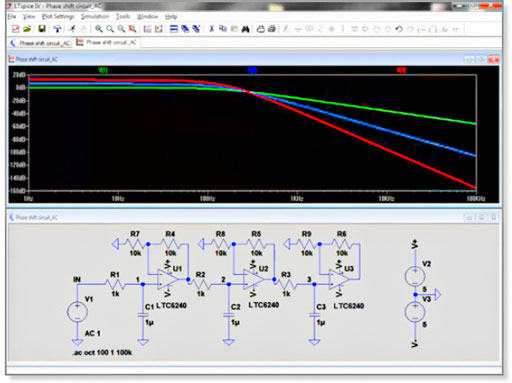

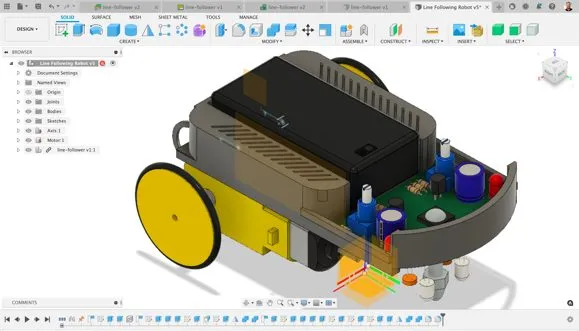

Autodesk Fusion 360

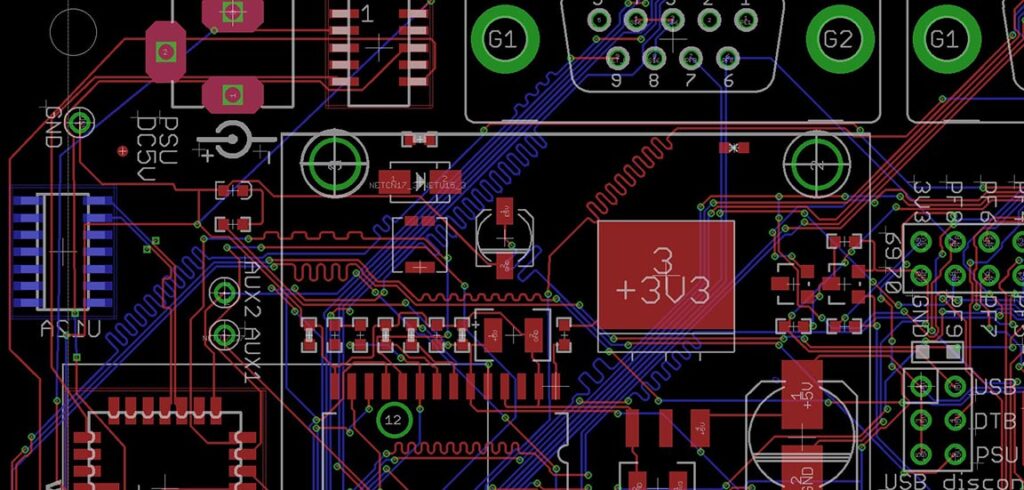

We are accustomed to designing products in Fusion 360, which is a software that has caught up with the capabilities of Solidworks, after many years of being in a free-trial beta version. Fusion 360 has become the industry standard for companies that want to design and manufacture using the same software. Fusion does just that – it fuses the two capabilities together in a single software suite. Fusion also incorporates electronic circuit board capabilities and sheet metal design, in addition to solid material designs. Fusion 360 also does machining simulation.

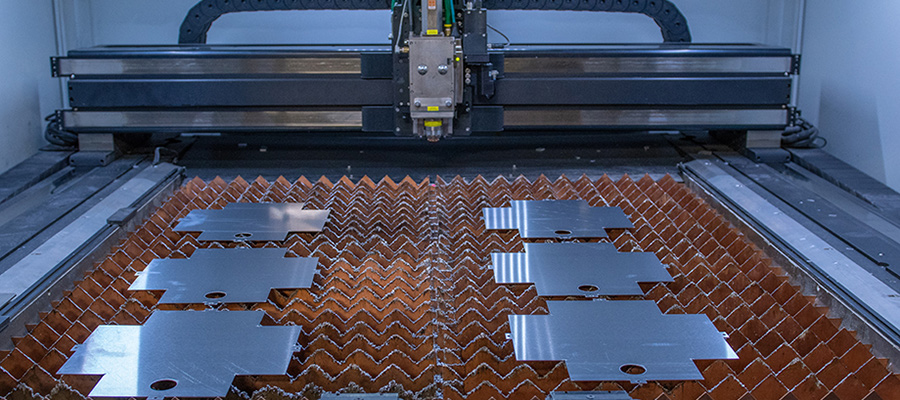

Mach 3 and CNC Prototyping

Electronic Launchpad has a small CNC machine and we use Mach 3 software to run the .tap files generated on Fusion 360. This software runs a variety of different CNC machines and is useful for testing CNC files before sending them off to a fabricator. Mach 3 provides a simulation screen that allows one to validate the file before running the job. This validation ensures that the parts are within the limits of the machine.

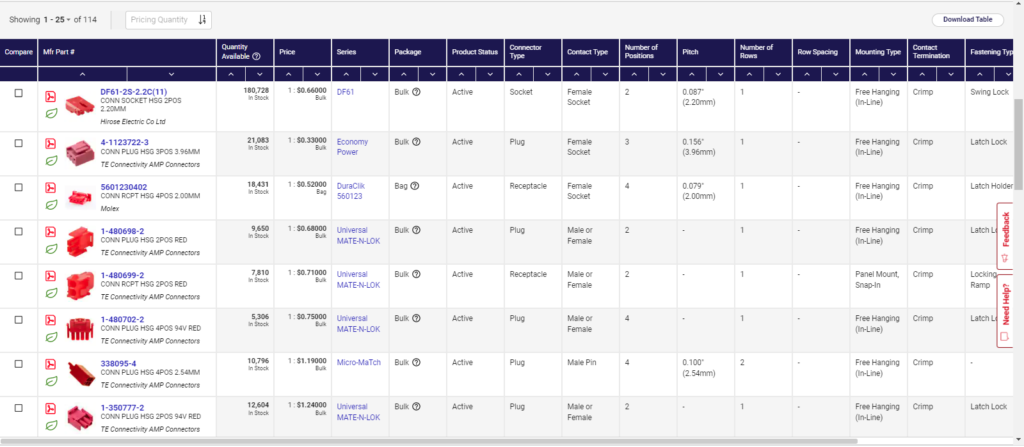

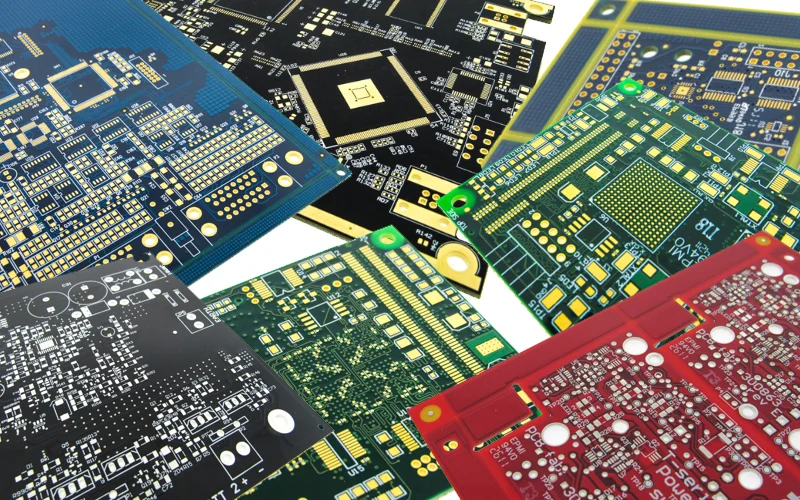

Manufacturing

Electronic Launchpad has workflows with other laser and CNC companies in Ontario, Canada that can provide cost-effective manufacturing. We also have a workflow to send out drawings for quotation from fabrication shops to get an even more competitive supply chain for mass production.